Pittsburgh, PA Lewis must wait for the barge to be completed before he can head down the Ohio. Perhaps by this date, the trenails are in place, and they are finishing the caulking and rigging.

Figure 1

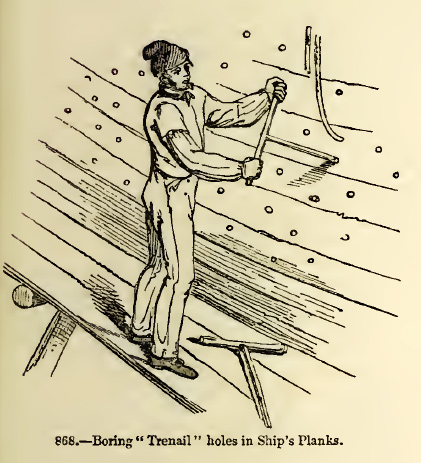

Boring “Trenail” Holes

From Palmer, Robert M. Palmer, The Pictorial Gallery of Arts, Figure 868.

Pittsburgh Ships

At and near this place, ship-building is an object of great attention. Several vessels are now on the stocks; and three have been launched this spring, from 160 to 275 tons burden.

—Thaddeus Harris[1]Thaddeus Harris, The Journal of a Tour into the Territory Northwest of the Alleghany Mountains Made in the Spring of the Year 1803, p. 43 in Reuben G. Thwaites, Travels West of the Alleghanies … Continue reading

Placing Trenails

The mode of fastening these planks to the timbers is not among the least important of the arrangements. While the plank is being held up in its place by screws, a man mounts on a scaffold [Fig. 1] and bores holes with an auger; these holes are from one to two inches in diameter, according to the thickness of the planks, and are bored not only through the plank, but also through the main timbers and through the inner planking. The labour of boring them is hence very severe, especially near the keel, where the man has to work nearly over his head. Into some of these holes bolts of copper or iron are driven; but the greater number of the holes are allowed to remain open for some time, that the wood around them may season, and then large wooden pegs called “trenails” are driven in. These trenails are cut out of sound oak, either by machines or by men who work with sharp tools, and are made from half a yard to a yard in length. Each trenail is slightly larger than the hole into which it is to be driven, so as to bite or hold firmly, and very powerful blows with a large hammer are required to drive it into its place: it is slightly longer than the depth of the hole, and the two ends are cut off after the driving. Finally, wedges are driven in at the ends, to tighten still more the trenail in the hole.[2]Robert M. Palmer, The Pictorial Gallery of Arts (London: Charles Knight and Co., 1905), page 218, downloaded from historicpittsburgh.org/islandora/object/pitt%3A31735060444753.

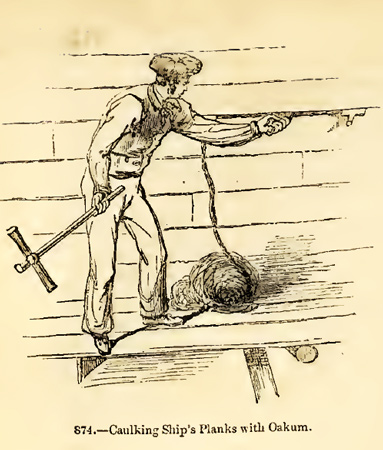

Caulking with Oakum

As a means of preventing water from entering between the planks, the seams are “caulked,” or filled up by strings of “oakum.” This oakum consists of old cables and ropes cut into pieces and picked asunder so as to form a mass of fibres; these fibres are rolled together as a kind of rude substitute for string, by means of the hand and a board placed in a sloping position. The threads of oakum thus rolled are made up into bundles, and taken to the ship’s side, where the caulker proceeds to use them. He drives in the threads by means of a hammer and an instrument called a “caulking-iron,” filling up every seam so densely that it not only prevents the entrance of water, but also strengthens the framework generally. [Fig. 2] Any little rents, holes, or fissures that may appear in the woodwork are similarly filled up with oakum. After this the whole is coated with a hot mixture of pitch and resin.[3]Ibid.

Notes

| ↑1 | Thaddeus Harris, The Journal of a Tour into the Territory Northwest of the Alleghany Mountains Made in the Spring of the Year 1803, p. 43 in Reuben G. Thwaites, Travels West of the Alleghanies (Cleveland: The Arthur H. Clark Co., 1904), p. 344. |

|---|---|

| ↑2 | Robert M. Palmer, The Pictorial Gallery of Arts (London: Charles Knight and Co., 1905), page 218, downloaded from historicpittsburgh.org/islandora/object/pitt%3A31735060444753. |

| ↑3 | Ibid. |